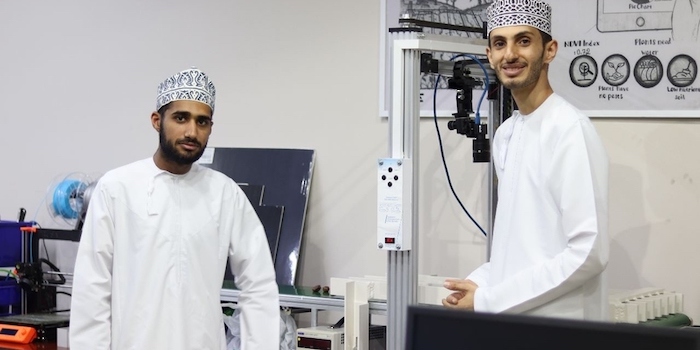

Muscat: A group of students from the College of Engineering at Sultan Qaboos University succeeded in making a technical innovation using computer vision, an artificial intelligence technique, and integrating it with robotic systems to automatically identify the quality of dates and introduce artificial intelligence technology into the food industries.

The project aims to increase food quality by using artificial intelligence to automate food inspection and sorting, increase factory production capacity, reduce the time required to inspect and sort dates, and effectively contribute to food security.

Asaad bin Saeed Al Hinai, a member of the student project team, said that the date industry is one of the important industries in the Sultanate of Oman, as it is one of the sources of income and trade. However, date producers face challenges in the sorting process, especially in identifying dates that are spoiled or unsuitable for human consumption. Artificial intelligence technology is important in improving the date sorting process in factories. We carried out a date sorting project using computer vision algorithms and robotics.

Al Hinai added that the system uses artificial intelligence to sort dates automatically. The system automates the process of sorting edible dates from spoiled ones, distinguishes the quality of dates automatically, identifies the condition of dates that pass through a production line using artificial intelligence, and then transfers them to the appropriate path. It also counts the number of dates that are sorted and the percentage of spoiled dates from good ones.

Ahmed bin Mohammed Al Habsi, a member of the student project team, explained that introducing artificial intelligence in food sorting is very important. It begins by bringing the dates into the production line via the conveyor belt. After that, the dates are photographed from the top of the production line using a high-resolution camera. The good dates are identified from the spoiled ones using computer vision. The dates are then sorted through special gates into a production line.

Saleh bin Yahya Al Ghanami, a member of the student project team, pointed out that factories face many challenges, such as manually sorting spoiled or unusable products. This method is considered economically expensive, and relying on the human factor may reduce the quality of dates.

Al Ghanami stated that the system's performance is measured in terms of the speed of sorting (the number of dates that are sorted within an hour) and the error rate of examination and sorting, stressing that the system increases the efficiency of the date sorting process compared to traditional methods.

It is worth noting that the artificial intelligence system can be introduced in other areas, such as inspection and quality control operations in various factories that need to precisely examine product quality.